China's Leading Lime Equipment Industry Provider

Professional Lime Kiln Equipment Manufacturer | Committed to delivering efficient, energy-saving, and eco-friendly solutions for our clients.

Shandong Tianhang Mechanical Equipment Co., Ltd. is a emerging technology-based private enterprise affiliated with the Shandong Tianhang Group. The company currently employs over 150 staff, including 52 engineering technicians, 34 of whom hold intermediate professional titles.

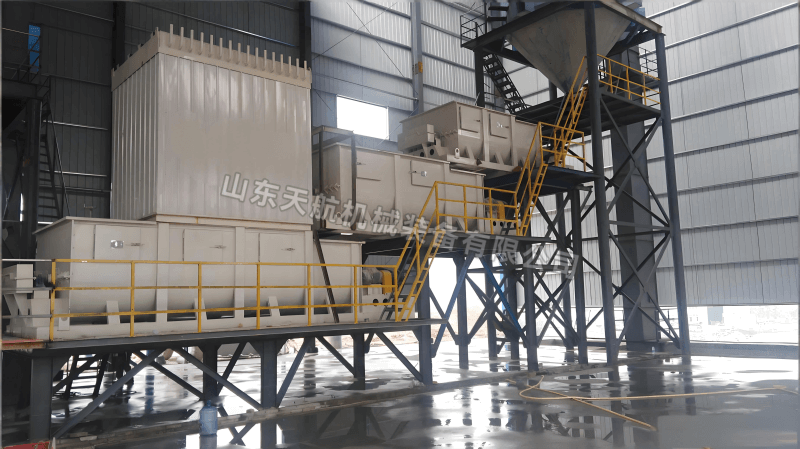

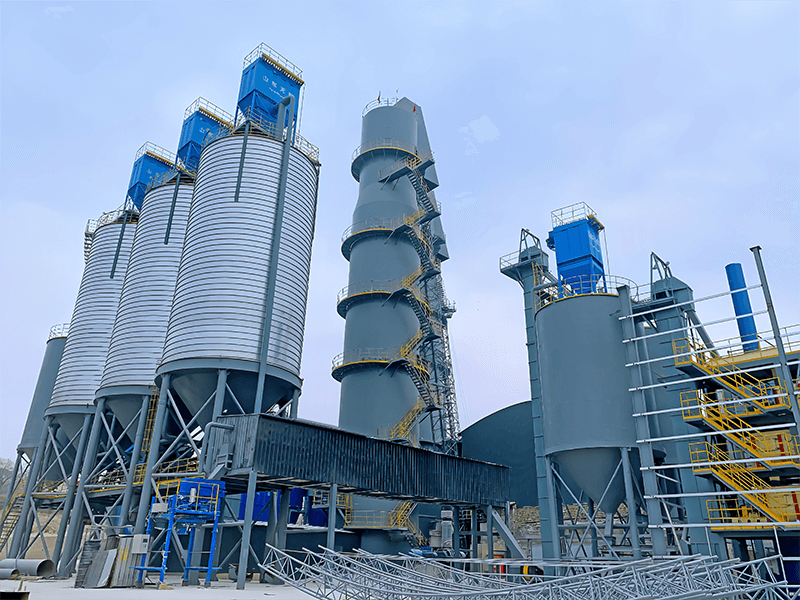

Occupying an area of more than 22,000 square meters, the company comprises machining, welding, and assembly workshops. It is equipped with 110 advanced machines, enabling high-precision processing across a wide range of applications. Since its inception, the company has implemented a high-standard, high-quality strategy. It has successfully completed the intelligent transformation and technical optimization of vertical lime kiln complete equipment in specifications ranging from φ3200 to φ5300 within China. These kilns are renowned for their excellent performance, reliable quality, and user-friendly operation. Leveraging its advantages in advanced technology, reliable quality, attentive service, and competitive pricing, the company has become a base for lime kiln equipment manufacturing, with its products selling well and receiving widespread acclaim across various regions.

In 2018, through a powerful alliance with Jiangsu Shengyuan Technology Co., Ltd., Shengyuan Tianhang Group was established. This made it one of the few domestic kiln producers with full qualifications, integrating design, manufacturing, installation, commissioning, and operation.

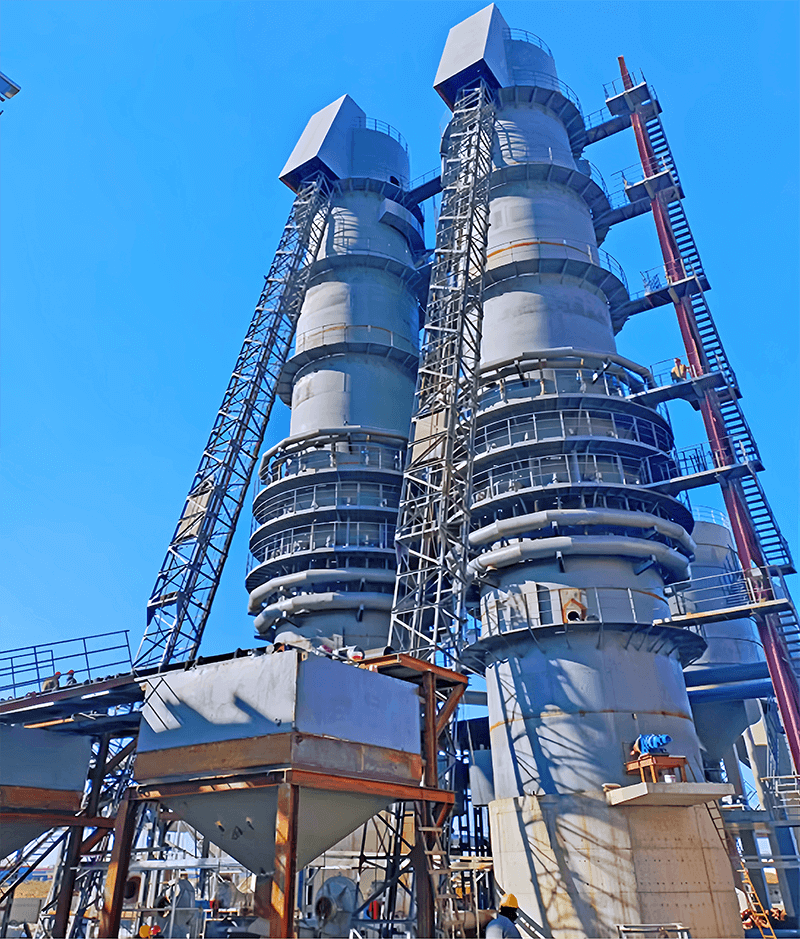

The company's independently developed vertical lime kiln, capable of using both gas and coal as fuel, holds more than ten patents. Furthermore, the rotary kilns, twin shaft kilns, and sleeve kilns produced by the company lead the industry in various performance indicators, including energy consumption, equipment operation, environmental protection, and product quality.

The large-scale hydraulic equipment components manufactured by the company were successfully trialed in the Xinjiang Aertashi Hydropower Station project, filling multiple domestic technical gaps.

Main Business Scope of Shandong Tianhang Mechanical Equipment Co., Ltd.:

1. Intelligent Vertical Mixed-Fuel Lime Kilns (using Gas/Coal): Complete equipment services (design, manufacturing, installation, commissioning, operation) for specifications: φ5300, φ4800, φ4000, φ3500, φ3200.

2. Intelligent Rotary Lime Kilns: Complete equipment services (design, manufacturing, installation, commissioning, operation) for daily capacities: 300 T/D, 600 T/D, 800 T/D, 1000 T/D.

3. Twin Shaft Kilns & Sleeve Kilns (using Gas/Coal): Complete equipment services (design, manufacturing, installation, commissioning, operation).

4. Various Environmental Protection Product Equipment: Complete services (design, manufacturing, installation, commissioning, operation).

5. Large-Scale Hydraulic Equipment: Production, manufacturing, installation, and commissioning.

Years of Expertise

Proven Success

Expert Team

Proprietary Patents

Click to Play

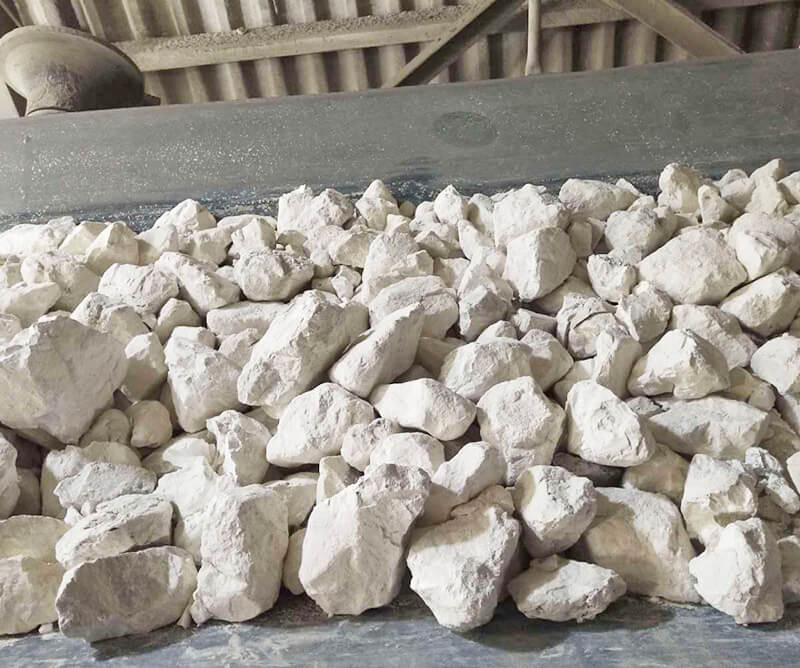

Tianhang Machinery provides a diverse range of lime kiln equipment designed to meet the varied needs of our customers. Our products are recognized for their high efficiency, energy savings, and eco-friendly features, earning widespread trust and approval from clients.

Corrosion and Rust Prevention for Calcium Hydroxide Equipment,As industrial machinery, calcium hydroxide equipment requires robust corrosion and rust prevention measures.

The calcination mechanism of double chamber kiln is full process co current calcination, with high lime activity and diverse fuels such as natural gas, coal gas, oil, coal powder, etc.

The calcination mechanism of double chamber kiln is full process co current calcination, with high lime activity and diverse fuels such as natural gas, coal gas, oil, coal powder, etc.

The calcination mechanism of double chamber kiln is full process co current calcination, with high lime activity and diverse fuels such as natural gas, coal gas, oil, coal powder, etc.

When using hydrated lime equipment, only by understanding its product characteristics can we prepare to make good use of this equipment.

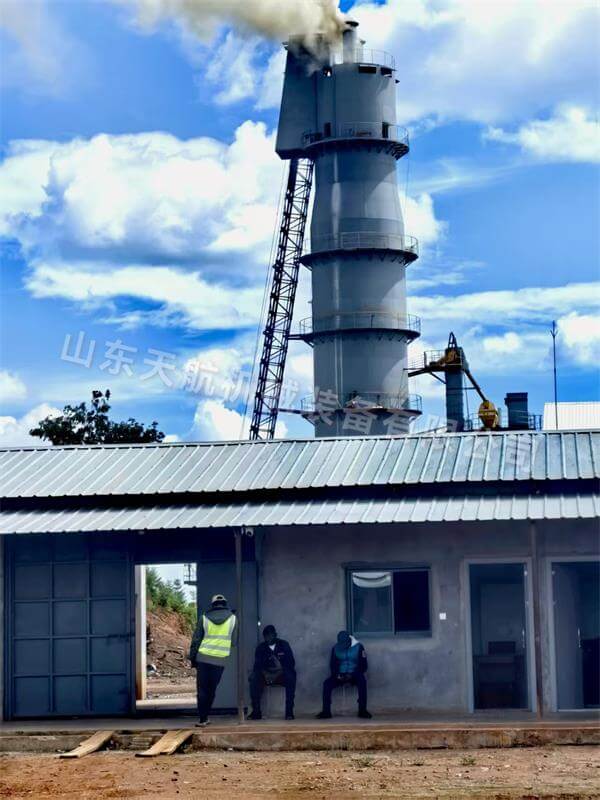

Our equipment has been successfully deployed in numerous enterprises both domestically and internationally, delivering significant economic benefits and environmental value to our clients.

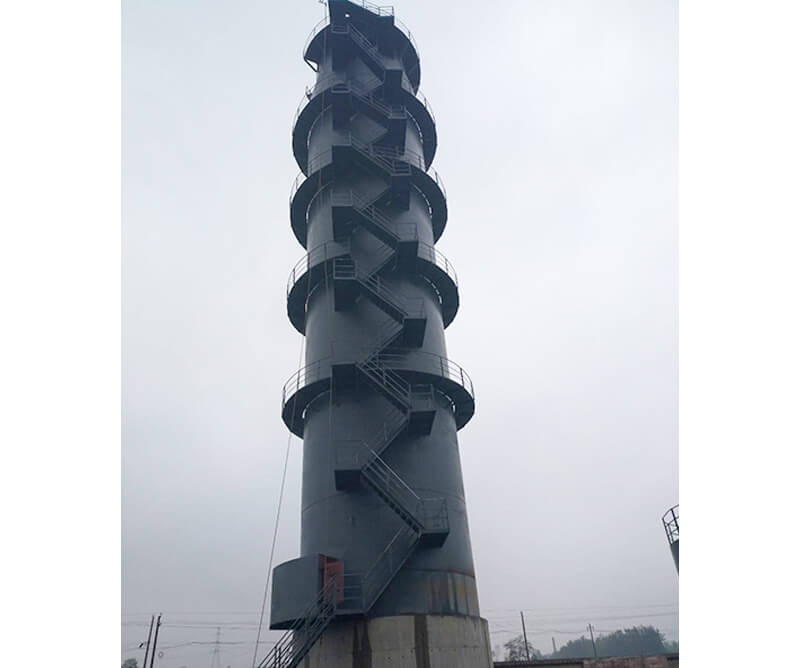

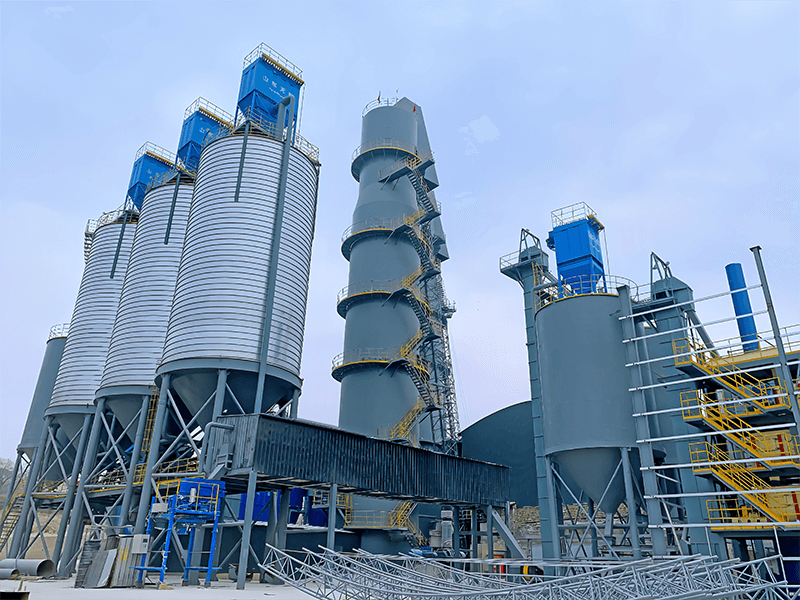

Project Introduction:2*300TPD dual-purpose gas and coal mixed firing vertical kiln

Project Introduction:EPC of 1 * 100TPD mixed fired lime vertical kiln

Project Introduction:1*200 TPD Mixed Burning Lime Vertical Kiln EPC

Project Introduction:

Project Introduction:

Project Introduction:

Project Introduction:

Project Introduction:Established on December 31, 2019, the furnace has an outer diameter of 7200mm and an inner diameter of 800mm, with a kiln shell height of 34.5m. It is equipped with four automated mixed firing environmentally friendly vertical kilns (each with a daily output of 300 tons).

Project Introduction:

We provide comprehensive service support, from project consultation and scheme design to equipment manufacturing, installation and commissioning, as well as technical training and maintenance in the later stage.

Provide professional project consulting and personalized solution design based on customer needs and site conditions to ensure the feasibility and economy of the project.

We adopt advanced manufacturing processes and strict quality control to ensure the quality and performance of the equipment, and provide professional installation and commissioning services to ensure the normal operation of the equipment.

Provide comprehensive technical training and a comprehensive after-sales service system, including equipment maintenance, troubleshooting, technical upgrades, etc., to ensure worry free use for customers.

Stay informed about the latest developments, technological innovations, and industry news of Tianhang Machinery

The environmentally friendly lime kiln is equipped with a dust discharge valve, which can reduce the heat transfer efficiency. Finding a suitable location during installation is crucial to ensure the effective operation of the lime kiln; Regularly check whether each operating system is normal, whether the dust exhaust valve operates flexibly, and whether its weight ratio is reasonable, neither too much nor too little. When there is too much, it can cause unstable punching, and in severe cases, it can lead to short circuits. When there is too little, it can result in poor sealing, loose closure, and internal air leakage. In severe cases, it can cause material collapse in the system.

View Details >>

The environmentally friendly lime kiln is equipped with a dust discharge valve, which can reduce the heat transfer efficiency. Finding a suitable location during installation is crucial to ensure the effective operation of the lime kiln; Regularly check whether each operating system is normal, whether the dust exhaust valve operates flexibly, and whether its weight ratio is reasonable, neither too much nor too little. When there is too much, it can cause unstable punching, and in severe cases, it can lead to short circuits. When there is too little, it can result in poor sealing, loose closure, and internal air leakage. In severe cases, it can cause material collapse in the system.

View Details >>

Calcium hydroxide equipment has a wide range of applications in chemical, building materials and other fields, and its installation process is crucial, directly related to the operational efficiency and safety of the equipment. Here are a few things to pay attention to when installing equipment:1. The preparation work before installation should be sufficient. Before installation, it is necessary to understand the structure, performance, and usage conditions of the equipment and develop a reasonable installation plan. At the same time, prepare the necessary tools and materials, such as lifting machinery, forklifts, screws, bolts, etc., and ensure their reliable quality.2. The basic production and inspection should be rigorous. Design and construct a suitable foundation structure based on the weight and usage requirements of the equipment, ensuring that the foundation has sufficient bearing capacity and stability. After the completion of the basic production, strict inspection is required, including the position of the foundation coordinates, elevation, and overall dimensions of the plan. Heavy equipment foundation preloading tests are also required to prevent uneven settlement of the foundation after equipment installation.3. The installation process of the equipment should be accurate. During the positioning process of the calcium hydroxide equipment, the levelness and verticality of the equipment should be ensured to avoid poor operation or damage caused by installation errors. At the same time, pay attention to the connection of pipelines and valves to ensure smooth fluid flow, and pay attention to the sealing and smoothness of pipelines to avoid leakage or blockage.4. The installation and debugging of the electrical part should be standardized. According to the design requirements, correctly connect electrical components with power and control circuits, and install and debug electrical protection devices to ensure the safety and stability of the equipment during operation.5. The debugging and acceptance after installation should be meticulous. Conduct no-load and load test runs to check whether the operation and performance indicators of each component of the equipment meet the requirements. After debugging is completed, acceptance work will be carried out to confirm that the equipment meets the design requirements and has the ability to operate normally.In summary, the installation of calcium hydroxide equipment is a complex and delicate process that requires sufficient preliminary preparation, rigorous foundation fabrication and inspection, accurate equipment placement and installation, standardized electrical installation and commissioning, as well as meticulous commissioning and acceptance. Only in this way can we ensure the smooth operation and efficient production of the equipment.

View Details >>

Calcium hydroxide equipment has a wide range of applications in chemical, building materials and other fields, and its installation process is crucial, directly related to the operational efficiency and safety of the equipment. Here are a few things to pay attention to when installing equipment:1. The preparation work before installation should be sufficient. Before installation, it is necessary to understand the structure, performance, and usage conditions of the equipment and develop a reasonable installation plan. At the same time, prepare the necessary tools and materials, such as lifting machinery, forklifts, screws, bolts, etc., and ensure their reliable quality.2. The basic production and inspection should be rigorous. Design and construct a suitable foundation structure based on the weight and usage requirements of the equipment, ensuring that the foundation has sufficient bearing capacity and stability. After the completion of the basic production, strict inspection is required, including the position of the foundation coordinates, elevation, and overall dimensions of the plan. Heavy equipment foundation preloading tests are also required to prevent uneven settlement of the foundation after equipment installation.3. The installation process of the equipment should be accurate. During the positioning process of the calcium hydroxide equipment, the levelness and verticality of the equipment should be ensured to avoid poor operation or damage caused by installation errors. At the same time, pay attention to the connection of pipelines and valves to ensure smooth fluid flow, and pay attention to the sealing and smoothness of pipelines to avoid leakage or blockage.4. The installation and debugging of the electrical part should be standardized. According to the design requirements, correctly connect electrical components with power and control circuits, and install and debug electrical protection devices to ensure the safety and stability of the equipment during operation.5. The debugging and acceptance after installation should be meticulous. Conduct no-load and load test runs to check whether the operation and performance indicators of each component of the equipment meet the requirements. After debugging is completed, acceptance work will be carried out to confirm that the equipment meets the design requirements and has the ability to operate normally.In summary, the installation of calcium hydroxide equipment is a complex and delicate process that requires sufficient preliminary preparation, rigorous foundation fabrication and inspection, accurate equipment placement and installation, standardized electrical installation and commissioning, as well as meticulous commissioning and acceptance. Only in this way can we ensure the smooth operation and efficient production of the equipment.

View Details >>

You need to know that most devices require installation and debugging during use. Therefore, calcium hydroxide equipment is no exception, and debugging work is also carried out during equipment installation. Now let's talk about installing and debugging equipment. Due to the fact that calcium hydroxide equipment is an integrated device, it occupies a large area and has multiple external conditions. This requires preparing the necessary equipment in advance according to the manufacturer's recommendations. External environment. When installing and debugging calcium hydroxide equipment, attention should be paid to mutual cooperation, that is, the cooperation between users and technicians. Firstly, prepare the necessary raw materials, labor, and lifting equipment for installation. This will greatly improve the efficiency of installation and debugging with the support of both parties, achieving a mutually beneficial situation.

View Details >>

You need to know that most devices require installation and debugging during use. Therefore, calcium hydroxide equipment is no exception, and debugging work is also carried out during equipment installation. Now let's talk about installing and debugging equipment. Due to the fact that calcium hydroxide equipment is an integrated device, it occupies a large area and has multiple external conditions. This requires preparing the necessary equipment in advance according to the manufacturer's recommendations. External environment. When installing and debugging calcium hydroxide equipment, attention should be paid to mutual cooperation, that is, the cooperation between users and technicians. Firstly, prepare the necessary raw materials, labor, and lifting equipment for installation. This will greatly improve the efficiency of installation and debugging with the support of both parties, achieving a mutually beneficial situation.

View Details >>