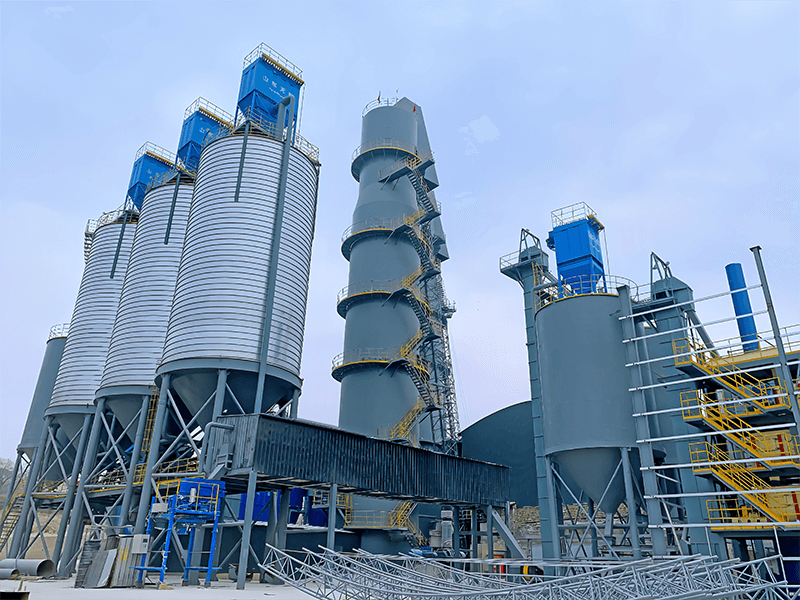

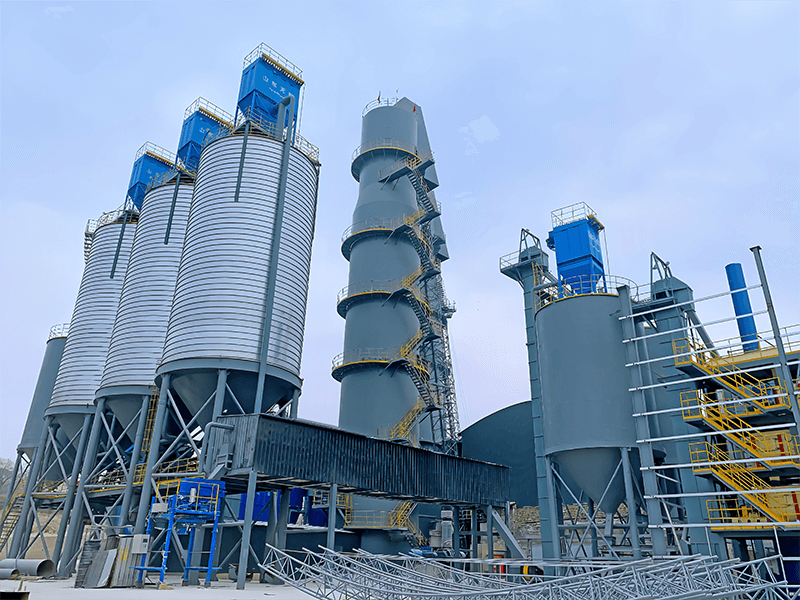

中国石灰装备行业先行者

专业石灰窑设备制造商 | 致力于为客户提供高效、节能、环保的解决方案

Corrosion and Rust Prevention for Calcium Hydroxide Equipment,As industrial machinery, calcium hydroxide equipment requires robust corrosion and rust prevention measures.

Corrosion and Rust Prevention for Calcium Hydroxide Equipment,As industrial machinery, calcium hydroxide equipment requires robust corrosion and rust prevention measures. Without proper protection, prolonged exposure to various factors will inevitably lead to oxidation and corrosion, ultimately causing operational failures and reduced lifespan. So, what are the effective methods to prevent rust? Let's explore.

The anti-corrosion strategies for calcium hydroxide equipment can be divided into two main categories:

1. Rust prevention for components before and after assembly: This primarily involves protecting exposed metal surfaces—areas not covered by paint.

2. Rust prevention during operational use: This falls under the user's maintenance responsibilities.

Specific methods include:

I. Anti-Corrosion Protection

- Painting

- Electroplating

- Use of corrosion-resistant alloys

II. Rust Prevention

1. Environmental Sealing

- Nitrogen purging

- Deoxygenation

- Dry storage

2. Contact Protection

- Application of anti-rust oils or greases

- Use of anti-corrosion liquids