中国石灰装备行业先行者

专业石灰窑设备制造商 | 致力于为客户提供高效、节能、环保的解决方案

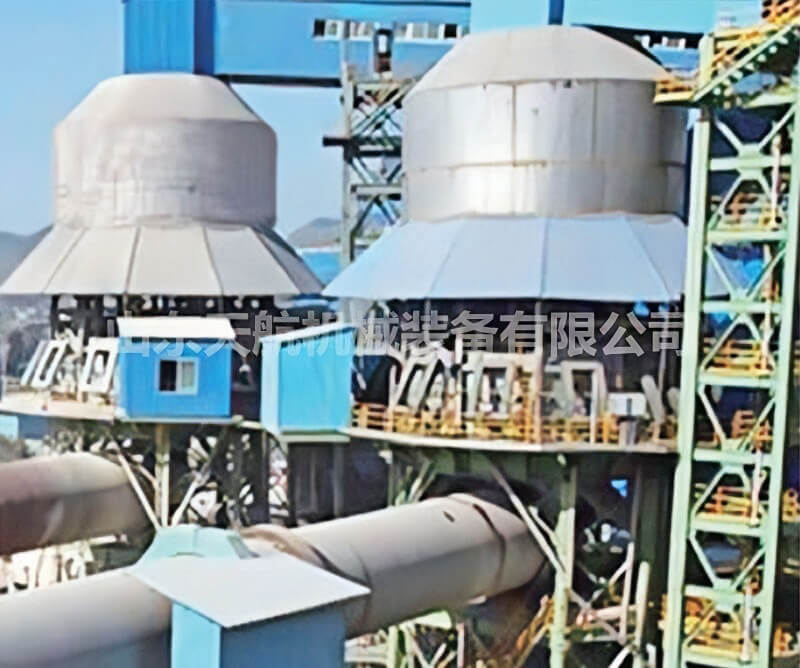

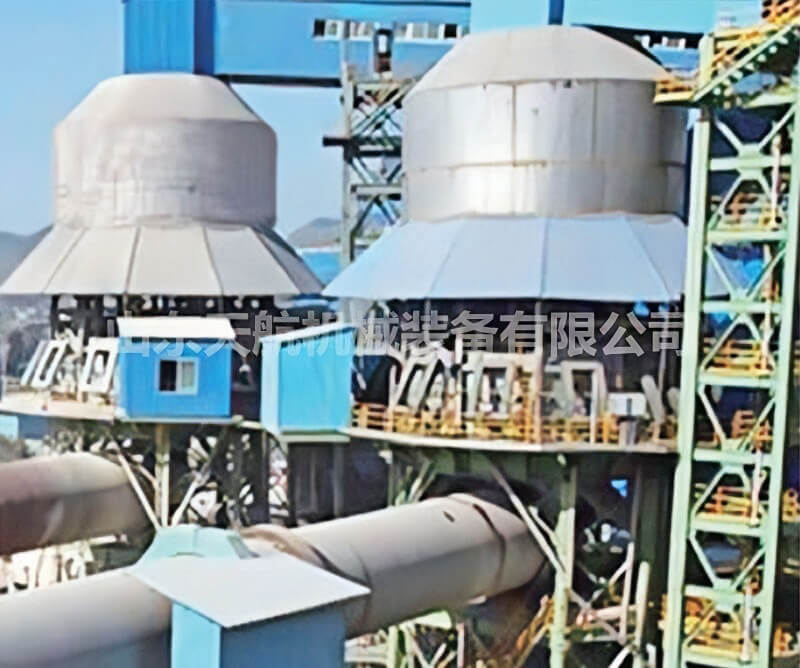

Rotary lime kilns can be divided into cement kilns, metallurgical and chemical kilns, and lime kilns according to the different materials processed. Cement kilns are mainly used for calcining cement clinker, and are divided into two categories: dry process cement kilns and wet process cement kilns. Metallurgical and chemical kilns are mainly used for magnetization roasting of poor iron ore in steel plants in the metallurgical industry; Oxidation roasting of chromium and nickel iron ores; Refractory plant roasting high alumina vanadium ore and aluminum plant roasting clinker, aluminum hydroxide; Chemical plants roast minerals such as chromite sand and chromite powder. Lime kiln (i.e. activated lime kiln) is used for roasting activated lime and lightly burned dolomite used in steel plants and ferroalloy plants.

The rotary lime kiln has a simple structure, smooth airflow, and timely discharge of sulfur-containing flue gas. The sulfur content in the fuel is not easily attached, resulting in low sulfur content and high purity of the calcined product, which meets the quality requirements of the finished product. At the same time, the material rolls in the circumferential direction and moves in the axial direction, with uniform heating. The temperature of the combustion device is easy to control, and the calcination quality is good and stable. The product activity can reach over 360ml.