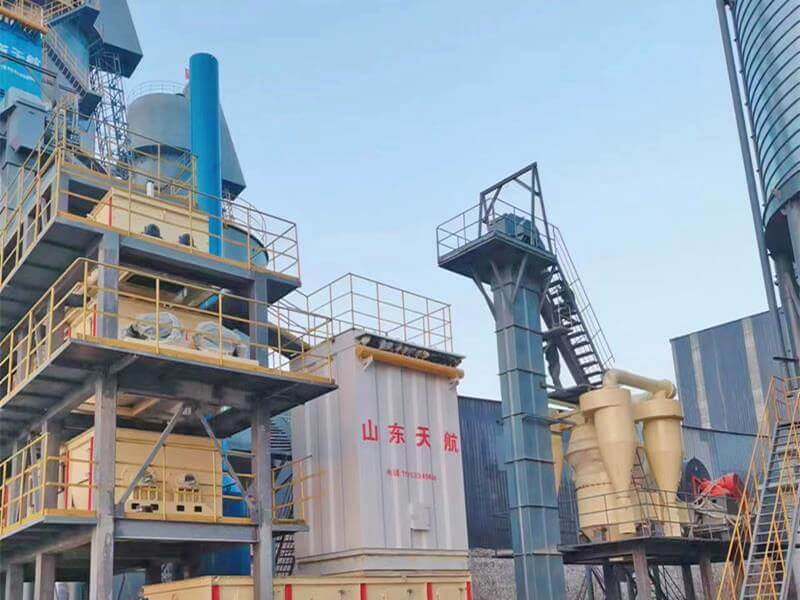

中国石灰装备行业先行者

专业石灰窑设备制造商 | 致力于为客户提供高效、节能、环保的解决方案

项目简介:2*300TPD dual-purpose gas and coal mixed firing vertical kiln

项目简介:EPC of 1 * 100TPD mixed fired lime vertical kiln

项目简介:1*200 TPD Mixed Burning Lime Vertical Kiln EPC

项目简介:

项目简介:

项目简介:

项目简介:

项目简介:Established on December 31, 2019, the furnace has an outer diameter of 7200mm and an inner diameter of 800mm, with a kiln shell height of 34.5m. It is equipped with four automated mixed firing environmentally friendly vertical kilns (each with a daily output of 300 tons).

项目简介:

项目简介:Founded in 2008, with 8 vertical kilns of 05.3Mx29.5M and 1 vertical kiln of 4.0Mx26.5M, the total annual output is currently 1 million tons. The main products are calcium oxide and soda ash raw materials, carbon dioxide gas. Since its production in 2009, it has been running normally and the products are excellent.

项目简介:The project was established in May 2022, consisting of a vertical automated controlled lime kiln with a daily output of 400 tons and a calcium hydroxide equipment production line with a capacity of 15-20 tons/hour. The product quality is excellent, and the following year, projects such as auxiliary equipment for calcium oxide mills were signed.

项目简介:Founded in 2018, there are 3 vertical kilns with a capacity of 05.3MX29.5M, and the total annual output is currently 300000 tons. The main product is calcium oxide. In addition to supplying our own Yuanlian Steel, some of our products are available for takeaway.

项目简介:This project was founded in 2010

项目简介:Established on May 31, 2019, with 3 units (with a daily output of 400 tons per unit), the furnace has an outer diameter of 7200mm and an inner diameter of 05300mm. It is an automated mixed firing environmentally friendly vertical kiln.

项目简介:Founded in 2016, it is a well-known large-scale enterprise in the domestic salt industry with 5 5.3MX29.5M vertical kilns. Currently, its total annual output is 500000 tons, and its main products are calcium oxide and soda ash raw materials, carbon dioxide gas. Since its production in 2016, it has been running normally and the products are excellent.

项目简介:The project was constructed in July 2023, with a daily output of 300 tons (lime vertical kiln) lime deep processing production line.

项目简介:Founded on July 29, 2019, it has 4 automated mixed firing environmental protection kilns (each with a daily output of 400 tons). The outer diameter of the furnace body is 7200mm, the inner diameter is 05300mm, and the height of the kiln shell is 36m.

项目简介:The project was established in November 2021, with 6 vertical automatic control lime kilns capable of producing 400 tons of gas and coal per day. The product quality is excellent, and the following year, 8 vertical automatic control lime kilns capable of producing 450 tons of gas and coal per day were signed.

项目简介:

项目简介:Guangxi Guigang Pingnan Jinda Mining Co., Ltd

项目简介:The project was initiated in November 2021, with a vertical lime production system capable of producing 300 tons per day.

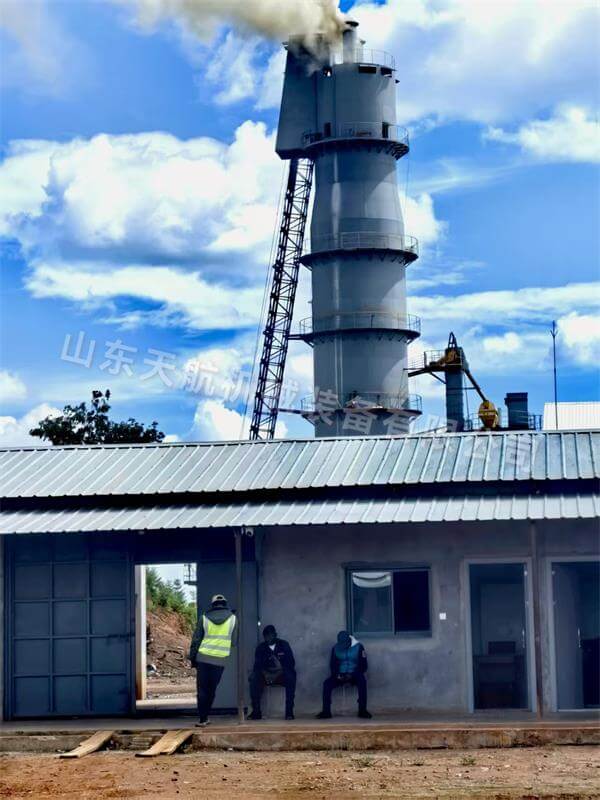

项目简介:Zijinpol Copper Company is a state-owned copper company in Serbia, which was once influenced by President Alexander. Wu Qiqi personally inspected. As one of the important projects of the company, the expansion of mines and smelters is undertaken by Shandong Tianhang with strong design strength, complete supporting facilities, strong construction force, and excellent technical equipment. The construction project was started on May 13, 2020, with two (each with a daily output of 400 tons) lime kiln systems, a 100000 ton/year lime grinding system, and a 30000 ton/year calcium hydroxide system

项目简介:The project was established in 2022, with two lime vertical kiln production lines and one calcium hydroxide production line capable of producing 350 tons per day.

项目简介:Established in March 2009, two 5.326m lime kilns with a daily output of 400 tons each, mainly producing calcium oxide

项目简介:The project is located about 40 kilometers from the center of Jinan, the capital of Shandong Province. There are two vertical kilns with a total capacity of 05.3MX24.5M and an annual output of 140000 tons. The main product is calcium oxide. It is a benchmark enterprise for environmental protection in Shandong Province.

项目简介:The renovation project of 22 lime kilns originally using blast furnace gas as fuel, now converted to standard coal. Before the renovation, each kiln produced approximately 80 tons of quicklime per day, while after the renovation, the daily output exceeded 120 tons per kiln. Since the renovation in 2017, the kilns have operated smoothly with high-quality products.